网站首页 >> 新闻中心

以球聚力促交流 德纳篮球创佳绩--德纳篮球队荣获2025园区“聚力杯”亚军

2025年8月3日,新材料科技园“聚力杯”篮球友谊赛在龙山湖未来体育中心圆满结束。经过为期四天紧张激烈、精彩纷呈的角逐,我司篮球队凭借出色的团队协作和顽强的拼搏精神,最终在巅峰对决中以微弱分差惜败,勇夺本次比赛亚...

发布时间:2025-08-14

钳住快乐,嗨吃一夏-- 德纳夏日龙虾节圆满结束

7月28日,为期四天的德纳夏日龙虾节,在满堂鲜香与欢声笑语里圆满结束。这场专属于味蕾的夏日狂欢,以盛夏特有的鲜美滋味,尽情犒赏着每一位德纳人。 双味争霸,舌尖上的狂欢盛宴 ...

发布时间:2025-07-28

团队齐心,智勇夺魁--第二届“敬业杯”员工知识竞赛圆满落幕

2025年6月26日,公司第二届“敬业杯”员工知识竞赛在热烈的氛围中成功举办。本次竞赛紧密结合全国安全生产月“人人讲安全,个个会应急——查找身边的安全隐患”这一主题,深度融入公司&ld...

发布时间:2025-07-03

赋能讲师,共同成长——半岛online(中国)2025年度内训师认证圆满收官

历经两个月的淬炼与沉淀,半岛online(中国)2025年度内训师认证工作圆满收官!22名学员在系统化培养中实现自我突破,顺利通过认证,光荣加入公司内训师队伍。 自今年3月起,学员们开启内训师成长之旅。依托“集中短训、微群磨课、现场演练、决胜...

发布时间:2025-06-10

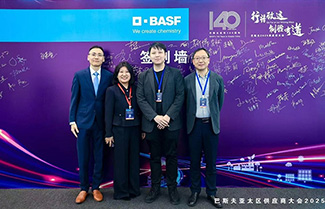

喜讯!半岛online(中国)荣获巴斯夫“年度绿电协作奖”

2025年4月8日,巴斯夫亚太区供应商大会在上海浦东举办。 半岛online(中国)总经理助理秦翊涵、销售总监梁甫军代表公司出席了此次盛会,并荣获巴斯夫全球采购总裁颁发的“年度绿电协作奖”荣誉证书。该奖项旨在表彰半岛online(中国)在绿色电力合作与低...

发布时间:2025-04-17

00后探厂:从象牙塔到智造前线

为助力25届应届生深度认知企业核心业务体系,直观感受公司实况与产业规模,构建全局思维,2025年4月9日,我司精心策划的“志在德纳,共创未来” 25届应届生探厂活动正式启幕。活动融合培训室拓展与厂区实地参访两大环节,以理论实践双轨并...

发布时间:2025-04-15

扫一扫

浏览我司移动平台

半岛网页版页面 版权所有(C)2024 网络支持 生意社 化工网 生意宝 著作权声明 网站地图 备案序号:苏ICP备05012787号